Units and Process Variables

| Description |

Equations |

| Units of force |

1 N1 lbf=1 kg⋅m/s2=32.174 lbm⋅ft/s2 |

| Weight |

W=mg |

| Gravitational acceleration |

g=9.8066 m/s2=32.174 ft/s2 |

Mass, volume and flow rate

| Description |

Equations |

| Mass flow rate |

m˙=dtdm |

| Volumetric flow rate |

V˙=dtdV |

| Molar flow rate |

n˙=dtdn |

| Density |

ρ=Vm=V˙m˙ |

| Specific volume |

v=mV=ρ1 |

| Molar volume |

Vm=nV=ρM |

| Specific gravity |

SG=ρrefρ |

| Description |

Equations |

| Mole and molecular wieght |

n=Mm |

| Mass fraction |

xA=mmA |

| Mole fraction |

yA=nnA |

Scaling factor of percent (%),

parts per million (ppm),

parts per billion (ppb) |

×100%×106 ppm×109 ppb |

| Average molecular weight |

M=∑ni∑mi=∑yiMi=(∑Mix1)−1 |

| Mass concentration |

ρA=VmA |

| Molar concentration |

cA=VnA |

| Molarity and molar |

1 M=1 mol/L |

| Description |

Equations |

| Pressure |

P=AF |

| Hydrostatic pressure |

P=P0+ρgh |

| Hydrostatic head |

P=ρgPh |

| Relationship between pressures |

Pabs=Patm+Pgauge |

| General manometer |

P1+ρ1gd1=P2+ρ2gda+ρmgh |

| Differential manometer |

P1−P2=(ρm−ρ)gh |

| Manometer for gas |

P1−P2=ρmgh=Ph |

| SCFM (standard cubic feet per minute) and ACFM (actual cubic feet per minute) |

Va˙=Vs˙PaPsTsTa (ideal gas) |

| Standard condition of gases |

natural gas - 59∘F,1 atm

other gas - 0∘C,1 atm |

| Description |

Equations |

| Conversion of temperature |

T(K)=T(∘C)+273.15T(∘R)=T(∘F)+459.67T(∘R)=1.8T(K)T(∘F)=1.8T(∘C)+32 |

| Conversion of temperature intervals |

1∘C=1.8∘F1∘R=1.8 K1∘F=1∘R1∘C=1.8 K |

| Description |

Equations |

| Balance equation |

Accumulation = Input - Output

+ Generation - Consumption |

| Fractional excess |

Fractional excess=nstoichnfed−nstoich |

| Fractional conversion |

Fractional conversion=nfednreacted |

| Fractional completion of limiting reactant |

Fractional completion=nfednreacted=nfed−νξ |

| Extent of reaction |

ξ=νini−ni0 |

| Extent of reaction in multiple reactions |

ni=ni0j∑νijξij |

Yield

theoretical = complete rxn, no side rxn |

Yield=ntheoreticalnactual×100 |

| Selectivity |

Selectivity=nundesiredndesired |

| Fractional excess of air (oxygen) |

Fractional excess air=nstoichnfed−nstoich |

| Quality of steam |

Quality of steam=mtotalmvapor |

| Description |

Equations |

| Nonreactive process |

−−No. unknown variablesNo. independent material balance speciesNo. other relations (process specifications)No. degrees of freedom |

Reactive process

Molecular species balance method

1 reaction system |

+−−No. unknown variablesNo. independent reactionNo. independent molecular speciesNo. other relationsNo. degrees of freedom |

Reactive process

Atomic species balance method

>1 reaction system |

−−−No. unknown variablesNo. independent reactive atomic speciesNo. independent nonreactive molecular speciesNo. other relationsNo. degrees of freedom |

Reactive process

Extent of reaction method

equilibrium problem |

+−−−No. unknown variablesNo. independent reactionNo. independent reactive speciesNo. independent nonreactive speciesNo. other relationsNo. degrees of freedom |

| Description |

Equations |

Estimations of density of liquid mixtures

1. Experimental data

2. Estimation formula

★ Volume addativity |

ρˉ1=i=1∑nρixiρˉ=i=1∑nxiρ1 |

| Incompressible approximation |

∂V^=0(∂P∂V^)T=0(∂T∂V^)P=0 |

| Volume expansivity |

β=V^1(∂T∂V^)P |

| Isothermal compressibility |

K=−V^1(∂P∂V^)T |

| Volume with change in T,P |

ln(V^1V^2)=β(T2−T1)−K(P2−P1) |

| Description |

Equations |

| Specific molar volume |

V^=nV |

Ideal gas equation of state

★ T>0∘C,P<1 atm |

PV=nRTPV^=RT |

| Standard conditions and actual conditions |

PsVs^PV=nTsT |

SCFM vs. ACFM

★ Ideal gas |

Va˙=Vs˙PaPsTsTa |

| Ideal gas condition |

T>0∘CP<1 atmV^ideal=PRT{>5 L/mol,80 ft3/lbmol>20 L/mol,320 ft3/lbmoldiatomicother |

| Description |

Equations |

| Partial pressure |

Pi=yiP |

| Dalton’s law |

∑Pi=P |

| Pure-component volume |

Vi=yiV |

| Amagat’s law |

∑Vi=V |

| Volume fraction of ideal gas |

yi=VVi |

| Description |

Equations |

| van der Waals equation of state |

P=V^−bRT−V^2a |

| Constant |

a=64Pc27R2Tc2 |

| Constant |

b=8PcRTc |

| Significance of 3 real roots |

V^highest=V^sat, vaporV^lowest=V^sat, liquidV^middle=no significance |

| Significance of real and imaginary roots |

V^real=V^gasV^imaginary=no significance |

| Description |

Equations |

| Virial equation of state |

RTPV^=1+V^B+V^2C+V^3D+⋯ |

| First order appox. of virial equation of state |

RTPV^=1+RTBP |

| Reduced temperature |

Tr=TcT |

| Reduced pressure |

Pr=PcP |

- Lookup Tc,Pc,ω

- Calculate Tr

- Estimate B by

- B0=0.083−Tr1.60.422

- B1=0.139−Tr4.20.172

- B=PcRTc(B0+ωB1)

- Substitute known values into first order approximation

| Description |

Equations |

| SRK equation of state |

P=V^−bRT−T0.5V^(V^+b)a |

| Constants |

a=0.4274R2Tc2.5/Pcb=0.08664RTc/Pc |

| Description |

Equations |

| SRK equation of state |

P=V^−bRT−V^(V^+b)αa |

| Constants |

a=0.4274(RTc)2/Pcb=0.08664RTc/Pcm=0.48508+1.55171ω−0.1561ω2Tr=T/Tcα=[1+m(1−Tr)]2 |

- Lookup Tc,Pc,ω

- Calculate a,b,m

- Determine the known

- If known T,V^

- Calculate Tr,α

- Solve from equation directly for P

- If known T,P

- Use equation and all knowns

- Use python to solve for V^

- If known P,V^

- Use equation, Tr,α, and all knowns

- Use python to solve for T

| Description |

Equations |

Compressibility

(Law of corresponding state) |

z=RTPV^ |

| Compressibility-factor equation of state |

PV^=zRT |

| Reduced temperature |

Tr=TcT |

| Reduced pressure |

Pr=PcP |

| Ideal reduced volume |

V^rideal=RTcPcV^ |

Kay’s rule of nonideal gas mixtures

Pseudocritical temperature |

Tc′=∑yiTci |

| Pseudocritical pressure |

Pc′=∑yiPci |

| Pseudoreduced temperature |

Tr′=Tc′T |

| Pseudoreduced pressure |

Pr′=Pc′P |

| Ideal pseudoreduced volume |

V^rideal=RTc′Pc′V^ |

- Lookup Tc,Pc

- If gas is HX2/He, adjust critical constant by Newton’s correlation

- Tca=Tc+8 K

- Pca=Pc+8 atm

- Calculate reduced value of two known variables from Tr,Pr,Vrideal

- Use compressibility chart to determine z

- Solve for unknowns from equation

| Description |

Equations |

| Clapeyron equation |

dtdP∗=TΔH^vVg^−Vl^1 |

| Clapeyron equation |

d(1/T)d(lnP∗)=−RΔH^v |

| Clausius-Clapeyron equation |

lnP∗=−RTΔH^v+B |

| Clausius-Clapeyron equation |

ln(P1P2)=−nRΔH^v(T21−T11) |

Antoine equation

(Vapor pressure of species) |

log10P∗=A−T+CB |

| Description |

Equations |

| Gibbs phase rule |

F=2+c−Π−r |

| Total vapor pressure of immiscible liquids |

P=∑Pi∗ |

Raoult’s law

★ Ideal gas and solution, non-dilute xA |

PA=yAP=xAPA∗(T) |

Henry’s law

★ Ideal gas and solution, dilute xA |

PA=yAP=xAHA(T) |

VLE of real gases

φ - fugacity coefficient

γ - activity coefficient |

yiφiP=xiγiP∗ |

Partition coefficient of ideal gas (Raoult’s law)

★ Ideal gas: φ=1,γ=1 |

Ki=xiyi=φiPγiPi∗=PPi∗ |

Partition coefficient of ideal gas (Henry’s law)

★ Ideal gas, Henry’s law assumptions |

Ki=PHi |

Saturation and humidity

| Description |

Equations |

| Relative saturation/humidity |

sr=PA∗(T)PA×100 |

| Molal saturation/humidity |

sm=P−PAPA |

| Absolute saturation/humidity |

sa=(P−PA)MAPAMA |

| Percent saturation/humidity |

sp=sm∗sm×100%=PA∗/(P−PA∗)PA/(P−PA)×100% |

Bubble and dew point

| Description |

Equations |

| Superheated vapor |

PA=yAP<PA∗(T) |

| Saturated vapor and dew point |

PA=yAP=PA∗(Tdp) |

| Degree of superheat |

T−Tdp |

| Bubble point temperature of mixture at constant P |

P=∑xiPi∗(Tbp) |

| Bubble point pressure of mixture at constant T |

Pbp=∑xiPi∗(T) |

| Dew point temperature of mixture at constant P |

∑Pi∗(Tdp)yi=1 |

| Dew point pressure of mixture at constant T |

Pdp=[∑Pi∗(T)yi]−1 |

| Description |

Equations |

| Kinetic energy |

Ek=21mv2 |

| Potential energy |

Ep=mgz |

| Internal energy |

U(T,V) |

| Total energy |

E=U+Ek+Ep |

| Work |

W=PΔV |

| Closed system balance |

ΔU+ΔEk+ΔEp=Q+W |

| ΔEk=0 |

Not accelerating |

| ΔEp=0 |

Not changing height |

| ΔU=0 |

No phase change, chemical reaction, temperature change |

| Q=0 |

Insulated system; adiabatic; temperature of system and surrounding the same |

| W=0 |

No moving parts, radiation, electric current, flow |

| Description |

Equations |

| Work |

W˙=W˙s+W˙fl |

| Enthalpy |

H=U+PV |

| Specific properties |

V^=mV,V^=nV |

| Open system balance |

ΔH˙+ΔE˙k+ΔE˙p=Q˙+W˙s |

| ΔEk=0 |

No acceleration; linear velocity of all streams the same |

| ΔEp=0 |

Stream entering and leaving at same height |

| Q˙=0 |

Insulated; adiabatic; system and surrounding temperature the same |

| W˙s=0 |

No moving parts |

| Friction loss |

F^=ΔU^−m˙Q˙ |

| Mechanical energy balance |

ρΔP+2Δv2+gΔz+F^=m˙W˙s |

Bernoulli equation

★ F^=0,W˙s=0 |

ρΔP+2Δv2+gΔz=0 |

| Description |

Equations |

| Internal energy |

ΔU=⎩⎪⎪⎪⎪⎨⎪⎪⎪⎪⎧=0≈0=0≈0(ideal gas)(real gas) P<10 bar(real gas) P>10 bar(condensed phases) |

| Enthalpy |

ΔH=⎩⎪⎪⎪⎪⎨⎪⎪⎪⎪⎧=0≈0=0≈V^ΔP(ideal gas)(real gas) P<10 bar(real gas) P>10 bar(condensed phases) |

Use (hypothetical) process paths to guide the use of equations.

| Description |

Equations |

| Heat capacity at constant volume |

CV(T)=(∂T∂U^)V |

| Heat capacity at constant pressure |

CP(T)=(∂T∂H^)P |

| Heat capacity correlation |

CP(T)=a+bT+cT2+dT3 |

| Heat capacity relation of condensed phases |

CP≈CV |

| Heat capacity relation of ideal gas |

CP=CV+R |

| Heat capacity of monoatmoic ideal gases |

CV=23R,CP=25R |

| Heat capacity of polyatomic ideal gases |

CV=25R,CP=27R |

Kopp’s rule

Heat capacity of compound (table B.10) |

CP,compound=∑νiCP,i |

Kopp’s rule

Heat capacity of mixture |

CP,mix=∑yiCP,i(T) |

| Change in internal energy at changing temperature |

ΔU^=∫T1T2CV(T) dT |

| Change in enthalpy at changing temperature |

ΔH^=∫T1T2CP(T) dT |

| Description |

Equations |

| Latent heat approximation of condensed phases |

ΔU≈ΔH |

| Latent heat approximation of ideal gas |

ΔUv≈ΔHv−RT |

| Description |

Equations |

| Heat of reaction of batch process |

ΔH=ξΔHrxn(T1,P1) |

| Heat of reaction of continuous process |

ΔH˙=ξΔH˙rxn(T1,P1) |

| Endothermic reaction |

ΔHrxn>0 |

| Exothermic reaction |

ΔHrxn<0 |

Hess’s law and heat of formation

“product minus reactant” |

ΔHrxn∘=i∑νiΔH^f,i∘ |

| Heat of formation conventions |

ΔH^f∘(elemental)=0 |

Hess’s law and heat of combustion

“reactant minus product” |

ΔHrxn∘=−i∑νiΔH^c,i∘ |

| Heat of combustion conventions |

ΔH^c∘(O2)=0ΔH^c∘(combustion product)=0

combustion product: COX2,HX2O,SOX2,NX2 |

Internal energy of reaction

(product ν>0; reactant ν<0) |

ΔUrxn=ΔHrxn−RTgas∑νi |

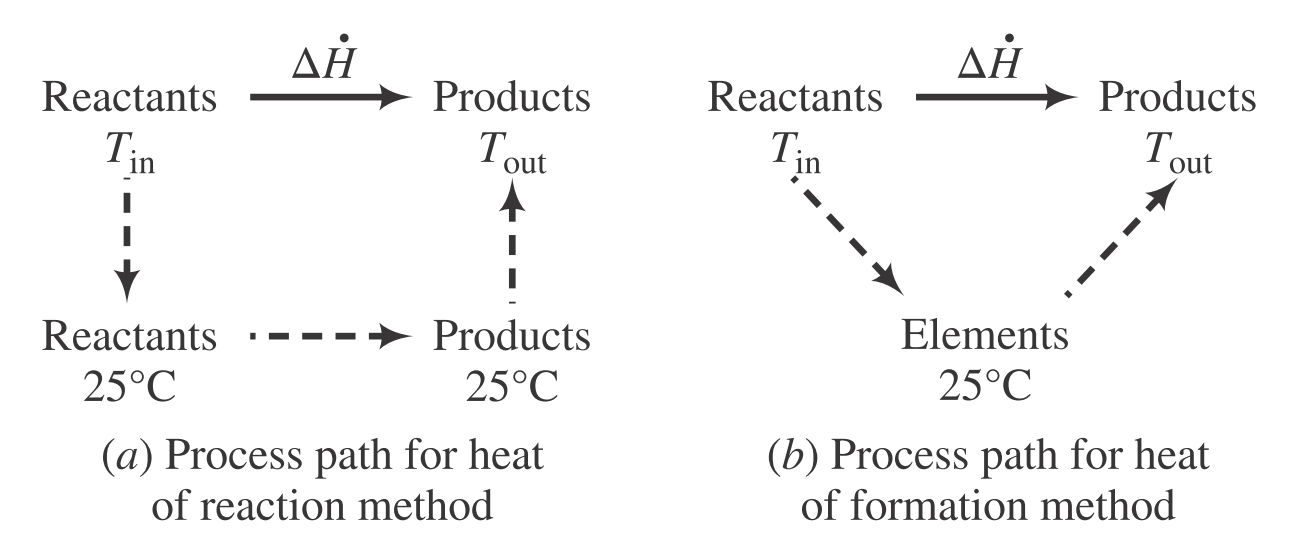

Reaction process paths. (Elementary Principles of Chemical Processes 4e by Felder et al. p507.)

Reaction process paths. (Elementary Principles of Chemical Processes 4e by Felder et al. p507.)

| Description |

Equations |

| Enthalpy change of heat of reaction method |

ΔH˙=rxn∑ξΔHrxn∘+∑n˙outH^out−∑n˙inH^in |

| Enthalpy change of heat of formation method |

ΔH˙=∑n˙outH^out−∑n˙inH^in |